|

On

Wednesday, March 28, 1979, 36 seconds after the hour of 4:00 a.m.,

several water pumps stopped working in the Unit 2 nuclear power plant

on Three Mile Island, 10 miles southeast of Harrisburg, Pennsylvania.1

Thus began the accident at Three Mile Island. In the minutes, hours,

and days that followed, a series of events -- compounded by equipment

failures, inappropriate procedures, and human errors and ignorance --

escalated into the worst crisis yet experienced by the nation's

nuclear power industry.

The accident focused

national and international attention on the nuclear facility at Three

Mile Island and raised it to a place of prominence in the minds of

hundreds of millions. For the people living in such communities as

Royalton, Goldsboro, Middletown, Hummelstown, Hershey, and Harrisburg,

the rumors, conflicting official statements, a lack of knowledge about

radiation releases, the continuing possibility of mass evacuation, and

the fear that a hydrogen bubble trapped inside a nuclear reactor might

explode were real and immediate. Later, Theodore Gross, provost of the

Capitol Campus of Pennsylvania State University located in Middletown

a few miles from TMI, would tell the Commission: On

Wednesday, March 28, 1979, 36 seconds after the hour of 4:00 a.m.,

several water pumps stopped working in the Unit 2 nuclear power plant

on Three Mile Island, 10 miles southeast of Harrisburg, Pennsylvania.1

Thus began the accident at Three Mile Island. In the minutes, hours,

and days that followed, a series of events -- compounded by equipment

failures, inappropriate procedures, and human errors and ignorance --

escalated into the worst crisis yet experienced by the nation's

nuclear power industry.

The accident focused

national and international attention on the nuclear facility at Three

Mile Island and raised it to a place of prominence in the minds of

hundreds of millions. For the people living in such communities as

Royalton, Goldsboro, Middletown, Hummelstown, Hershey, and Harrisburg,

the rumors, conflicting official statements, a lack of knowledge about

radiation releases, the continuing possibility of mass evacuation, and

the fear that a hydrogen bubble trapped inside a nuclear reactor might

explode were real and immediate. Later, Theodore Gross, provost of the

Capitol Campus of Pennsylvania State University located in Middletown

a few miles from TMI, would tell the Commission:

Never before have

people been asked to live with such ambiguity. The TMI accident --

an accident we cannot see or taste or smell ... is an accident that

is invisible. I think the fact that it is invisible creates a sense

of uncertainty and fright on the part of people that may well go

beyond the reality of the accident itself.2

The reality of the accident, the realization that such an accident

could actually occur, renewed and deepened the national debate over

nuclear safety and the national policy of using nuclear reactors to

generate electricity.

Three Mile Island is home to two nuclear power plants, TMI-1 and

TMI-2. Together they have a generating capacity of 1,700 megawatts,

enough electricity to supply the needs of 300,000 homes. The two

plants are owned jointly by Pennsylvania Electric Company, Jersey

Central Power & Light Company, and Metropolitan Edison Company, and

operated by Met Ed. These three companies are subsidiaries of General

Public Utilities Corporation, an electric utility holding company

headquartered in Parsippany, New Jersey.3

Each TMI plant is powered by its nuclear reactor. A reactor's function

in a commercial power plant is essentially simple -- to heat water.

The hot water, in turn, produces steam, which drives a turbine that

turns a generator to produce electricity. Nuclear reactors are a

product of high technology. In recent years, nuclear facilities of

generating capacity much larger than those of earlier years --

including TMI-1 and TMI-2 — have gone into service.4

A nuclear reactor generates heat as a result of nuclear fission, the

splitting apart of an atomic nucleus, most often that of the heavy

atom uranium. Each atom has a central core called a nucleus. The

nuclei of atoms typically contain two types of particles tightly bound

together: protons, which carry a positive charge, and neutrons, which

have no charge. When a free neutron strikes the nucleus of a uranium

atom, the nucleus splits apart. This splitting -- or fission --

produces two smaller radioactive atoms, energy, and free neutrons.

Most of the energy is immediately converted to heat. The neutrons can

strike other uranium nuclei, producing a chain reaction and continuing

the fission process. Not all free neutrons split atomic nuclei. Some,

for example, are captured by atomic nuclei. This is important, because

some elements, such as boron or cadmium, are strong absorbers of

neutrons and are used to control the rate of fission, or to shut off a

chain reaction almost instantaneously.5

Uranium fuels all nuclear reactors used commercially to generate

electricity in the United States. At TMI-2, the reactor core holds

some 100 tons of uranium. The uranium, in the form of uranium oxide,

is molded into cylindrical pellets, each about an inch tall and less

than half-an-inch wide. The pellets are stacked one atop another

inside fuel rods. These thin tubes, each about 12 feet long, are made

of Zircaloy-4, a zirconium alloy. This alloy shell -- called the

"cladding" -- transfers heat well and allows most neutrons to pass

through.6

TMI-2's reactor contained 36,816 fuel rods -- 208 in each of its 177

fuel assemblies. A fuel assembly contains not only fuel rods, but

space for cooling water to flow between the rods and tubes that may

contain control rods or instruments to measure such things as the

temperature inside the core. TMI-2's reactor has 52 tubes with

instruments and 69 with control rods.7

Control rods contain materials that are called "poisons" by the

nuclear industry because they are strong absorbers of neutrons and

shut off chain reactions. The absorbing materials in TMI-2's control

rods are 80 percent silver, 15 percent indium, and 5 percent cadmium.

When the control rods are all inserted in the core, fission is

effectively blocked, as atomic nuclei absorb neutrons so that they

cannot split other nuclei. A chain reaction is initiated by

withdrawing the control rods. By varying the number of and the length

to which the control rods are withdrawn, operators can control how

much power a plant produces. The control rods are held up by magnetic

clamps. In an emergency, the magnetic field is broken and the control

rods, responding to gravity, drop immediately into the core to halt

fission. This is called a "scram."

The nuclear reactors used in commercial power plants possess several

important safety features. They are designed so that it is impossible

for them to explode like an atomic bomb. The primary danger from

nuclear power stations is the potential for the release of radioactive

materials produced in the reactor core as the result of fission. These

materials are normally contained within the fuel rods.

Damage to the fuel rods can release radioactive material into the

reactor's cooling water and this radioactive material might be

released to the environment if the other barriers -- the reactor

coolant system and containment building barriers -- are also breached.8

A nuclear plant has three basic safety barriers, each designed to

prevent the release of radiation. The first line of protection is

the fuel rods themselves, which trap and hold radioactive

materials produced in the uranium fuel pellets.

The second barrier consists of the reactor vessel and the closed

reactor coolant system loop. The TMI-2 reactor vessel, which holds the

reactor core and its control rods, is a 40-foot high steel tank with

walls 8-½ inches thick. This tank, in turn, is surrounded by two,

separated concrete- and-steel shields, with a total thickness of up to

9-½ feet, which absorb radiation and neutrons emitted from the reactor

core. Finally, all this is set inside the containment building, a

193-foot high, reinforced-concrete structure with walls 4 feet thick.9

To supply the steam that runs the turbine, both plants at TMI rely on

a type of steam supply system called a pressurized water reactor. This

simply means that the water heated by the reactor is kept under high

pressure, normally 2,155 pounds per square inch in the TMI-2 plant.

In normal operations, it is important in a pressurized water reactor

that the water that is heated in the core remain below "saturation" --

that is, the temperature and pressure combination at which water boils

and turns to steam. In an accident, steam formation itself is not a

danger, because it too can help cool the fuel rods, although not as

effectively as the coolant water. But problems can occur if so much of

the core's coolant water boils away that the core becomes uncovered.

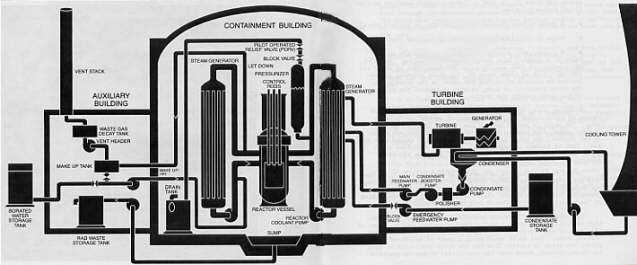

Schematic of the TMI-2 facility |

|

An uncovered core

may lead to two problems. First, temperature may rise to a point,

roughly 2,200°F, where a reaction of water and the cladding could

begin to damage the fuel rods and also produce hydrogen. The other

is that the temperature might rise above

the melting

point of the uranium fuel, which is about 5,200°F. Either poses a

potential danger. Damage to the zirconium cladding releases some

radioactive materials trapped inside the fuel rods into the core's

cooling water. A melting of the fuel itself could release far more

radioactive materials. If a significant portion of the

fuel should

melt, the molten fuel could melt through the reactor vessel itself

and release large quantities of radioactive materials into the

containment building. What might happen following such an event is

very complicated and depends on a number of variables such as the

specific characteristics of the materials on which a particular

containment building is constructed.10

The essential

elements of the TMI-2 system during normal operations include:

• The reactor,

with its fuel rods and control rods.

• Water, which

is heated by the fission process going on inside the fuel rods

to ultimately produce steam to run the turbine. This water, by

removing heat, also keeps the fuel rods from becoming

overheated.

• Two steam

generators, through which the heated water passes and gives up

its heat to convert cooler water in another closed system to

steam.

• A steam

turbine that drives a generator to produce electricity.

• Pumps to

circulate water through the various systems.

• A

pressurizer, a large tank that maintains the reactor water at a

pressure high enough to prevent boiling. At TMI-2 the

pressurizer tank usually holds 800 cubic feet of water and 700

cubic feet of steam above it. The steam pressure is controlled

by heating or cooling the water in the pressurizer. The steam

pressure, in turn, is used to control the pressure of the water

cooling the reactor.

Normally, water

to the TMI-2 reactor flows through a closed system of pipes called

the "reactor coolant system" or "primary loop." The water is

pushed through the reactor by four reactor coolant pumps, each

powered by a 9,000 horsepower electric motor. In the reactor, the

water picks up heat as it flows around each fuel rod. Then it

travels through 36-inch diameter, stainless steel pipes shaped

like and called "candy canes," and into the steam generators.

In the steam

generators, a transfer of heat takes place. The very hot water

from the reactor coolant system travels down through the steam

generators in a series of corrosion-resistant tubes Meanwhile,

water from another closed system -- the feedwater system or

secondary loop" -- is forced into the steam generator.

The feedwater in

the steam generators flows around the tubes that contain the hot

water from the reactor coolant system. Some of this heat is

transferred to the cooler feedwater, which boils and becomes

steam. Just as it would be in a coal- or oil-fired generating

plant, the steam is carried from the two steam generators to turn

the steam turbine, which runs the electricity-producing

generator.

The water from

the reactor coolant system, which has now lost some of its heat,

is pumped back to the reactor to pass around the fuel rods, pick

up more heat, and begin its cycle again.

The water from

the feedwater system, which has turned to steam to drive the

turbine, passes through devices called condensers. Here, the steam

is condensed back to water, and is forced back to the steam

generators again.

The condenser

water is cooled in the cooling towers. The water that cools the

condensers is also in a closed system or loop. It cools the

condensers, picks up heat, and is pumped to the cooling towers,

where it cascades along a series of steps. As it does, it releases

its heat to the outside air, creating the white vapor plumes that

drift skyward from the towers. Then the water is pumped back to

the condensers to begin its cooling process over again.

Neither the water

that cools the condensers, nor the vapor plumes that rise from the

cooling towers, nor any of the water that runs through the

feedwater system is radioactive under normal conditions. The water

that runs through the reactor coolant system is radioactive, of

course, since it has been exposed to the radioactive materials in

the core.

The turbine, the

electric generator it powers, and most of the feedwater system

piping are outside the containment building in other structures.

The steam generators, however, which must be fed by water from

both the reactor coolant and feedwater systems, are inside the

containment building with the reactor and the pressurizer tank.

A nuclear power

facility is designed with many ways to protect against system

failure. Each of its major systems has an automatic backup system

to replace it in the event of a failure. For example, in a

loss-of-coolant accident (LOCA) -- that is, an accident in which

there is a loss of the reactor's cooling water -- the Emergency

Core Cooling System (ECCS) automatically uses existing plant

equipment to ensure that cooling water covers the core.

In a LOCA, such

as occurred at TMI-2, a vital part of the ECCS is the High

Pressure Injection (HPI) pumps, which can pour about 1,000 gallons

a minute into the core to replace cooling water being lost through

a stuck-open valve, broken pipe, or other type of leak. But the

ECCS can be effective only if plant operators allow it to keep

running and functioning as designed. At Three Mile Island, they

did not. |

|